Download

Please provide the following details :

This field is required

This field is required

Please enter valid email (e.g. johnsmith@domain.com)

Please provide the following details :

This field is required

This field is required

Please enter valid email (e.g. johnsmith@domain.com)

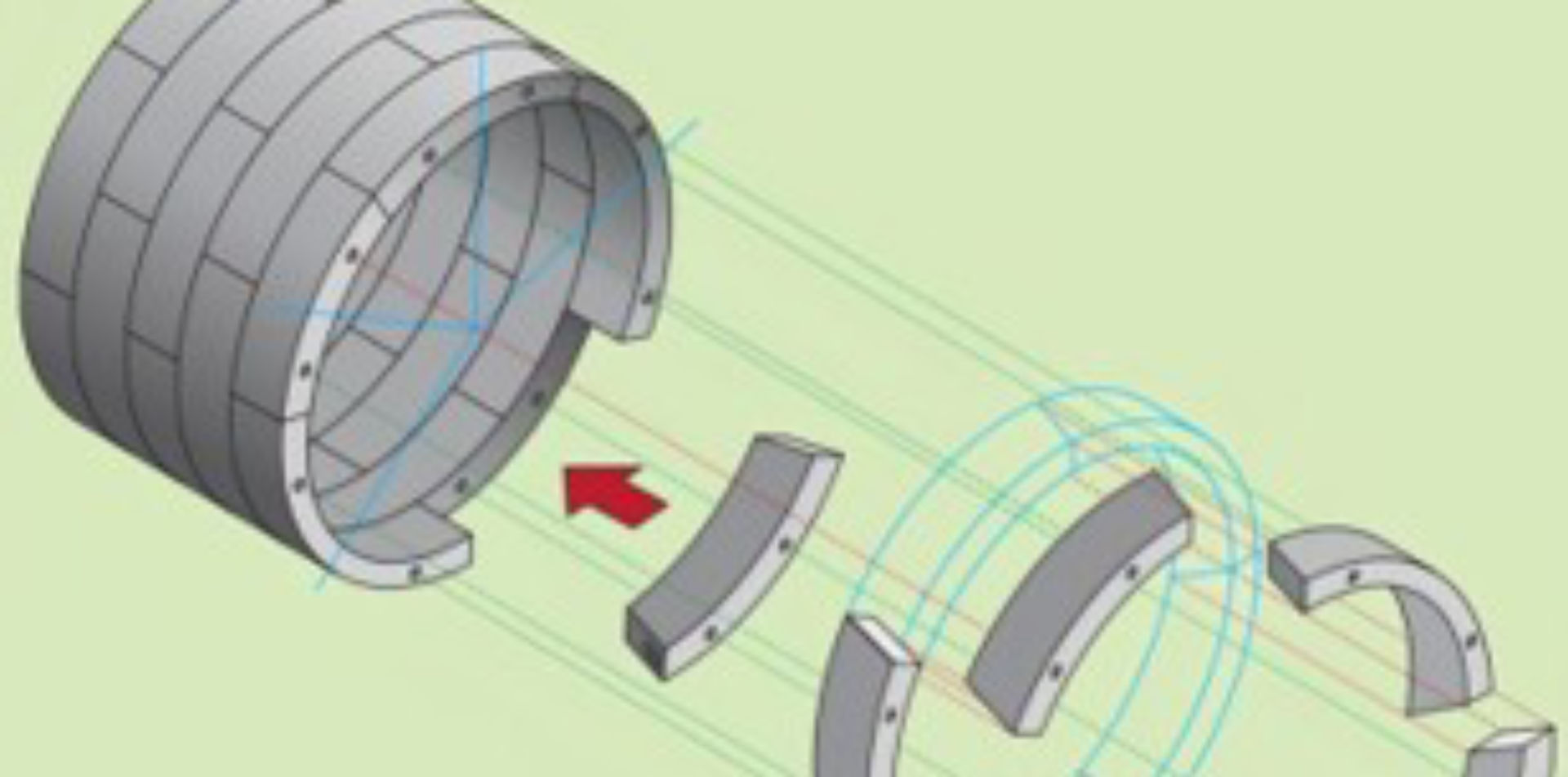

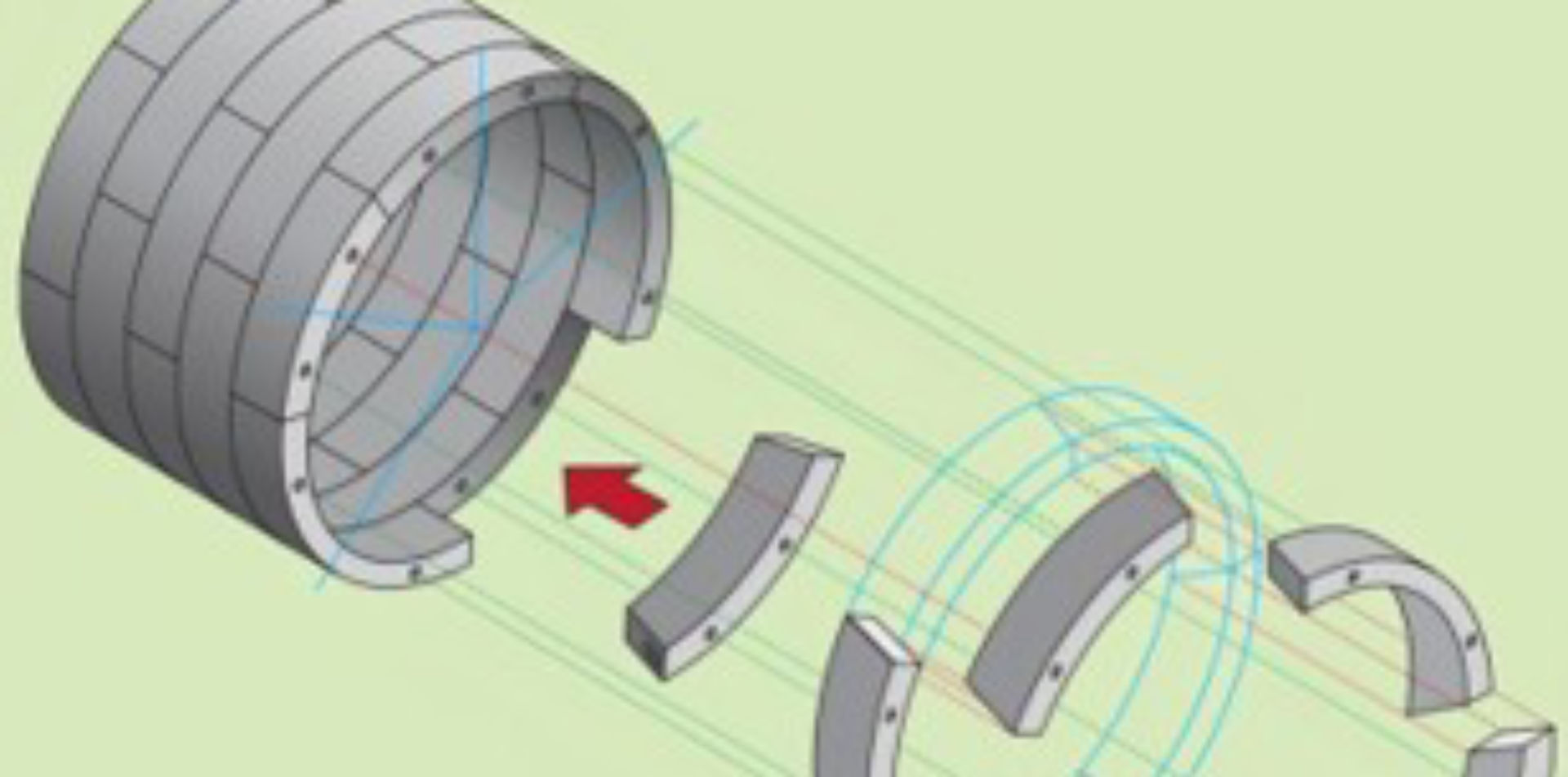

The tunneling industry is embracing durability and sustainability with Fiber-Reinforced Concrete (FRC) segments. Traditionally, tunnel linings relied on steel rebar reinforcement, but recent advancements show that incorporating steel fibers into precast concrete segments offers significant environmental, economic, and structural benefits.

Steel fibers have been used in concrete since the 1970s, but their application in tunnel linings gained traction after the introduction of international design guidelines like fib Model Code 2010 and fib Bulletin 83. These standards have boosted confidence among designers and contractors, paving the way for widespread adoption.

Modern tunnel projects demand higher compressive strength segments (C40–C70) for durability and faster production cycles. Steel fibers, with tensile strengths of 1,800–2,200 MPa, provide ductility and crack control essential for serviceability and ultimate limit states. Beam bending tests, as per EN 14651, confirm FRC’s superior performance in post-crack tensile strength.

A tunnel designed and built to last 100 years dramatically reduces environmental impact compared to one lasting only 50 years. FRC segments not only extend service life but also deliver first-cost savings, making them a smart investment for sustainable infrastructure.

FRC solutions are redefining tunnel construction by combining strength, sustainability, and cost-effectiveness. As urban infrastructure faces growing demands, adopting FRC segments ensures projects meet both performance and environmental goals.