Download

Please provide the following details :

This field is required

This field is required

Please enter valid email (e.g. johnsmith@domain.com)

Please provide the following details :

This field is required

This field is required

Please enter valid email (e.g. johnsmith@domain.com)

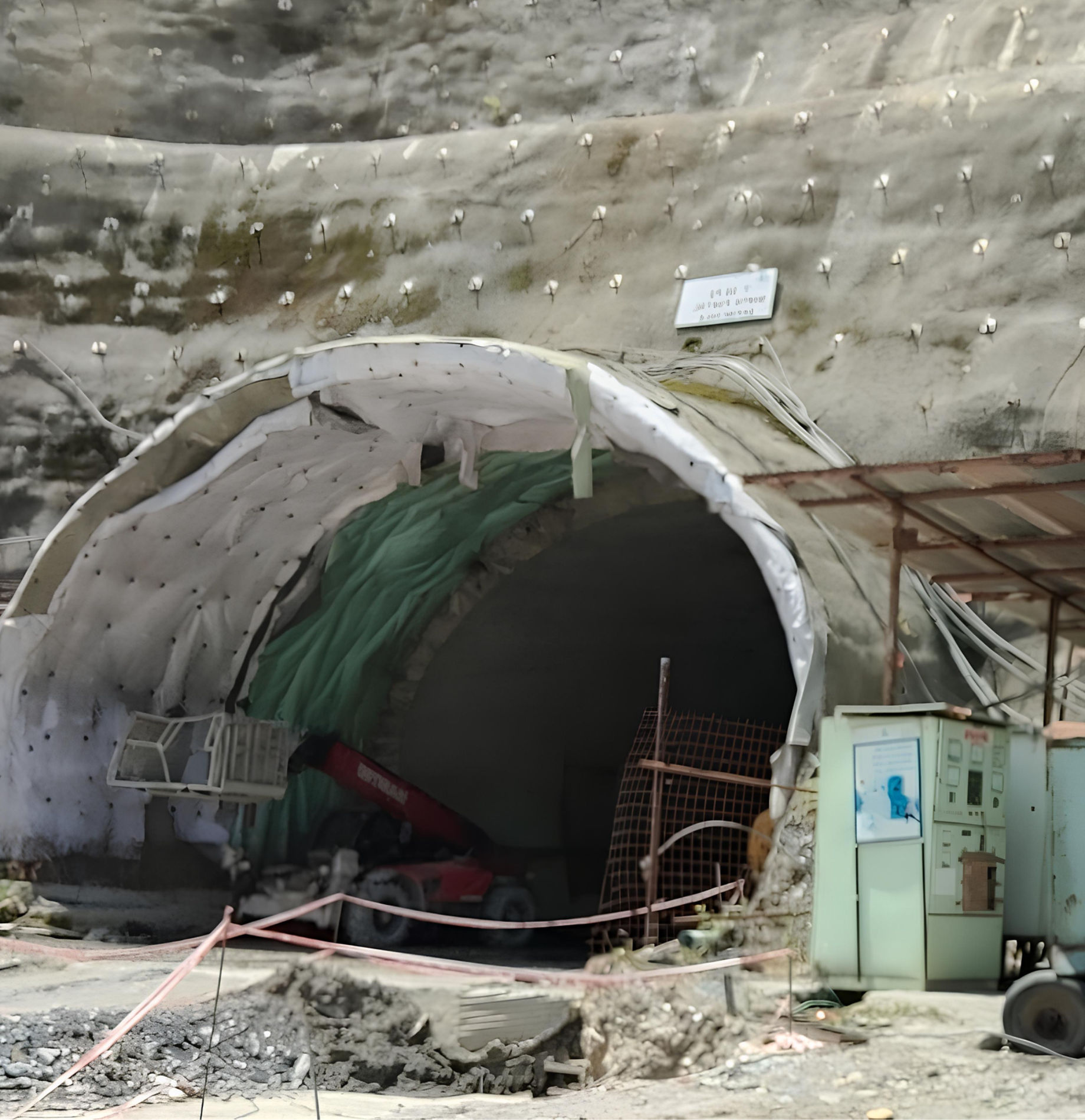

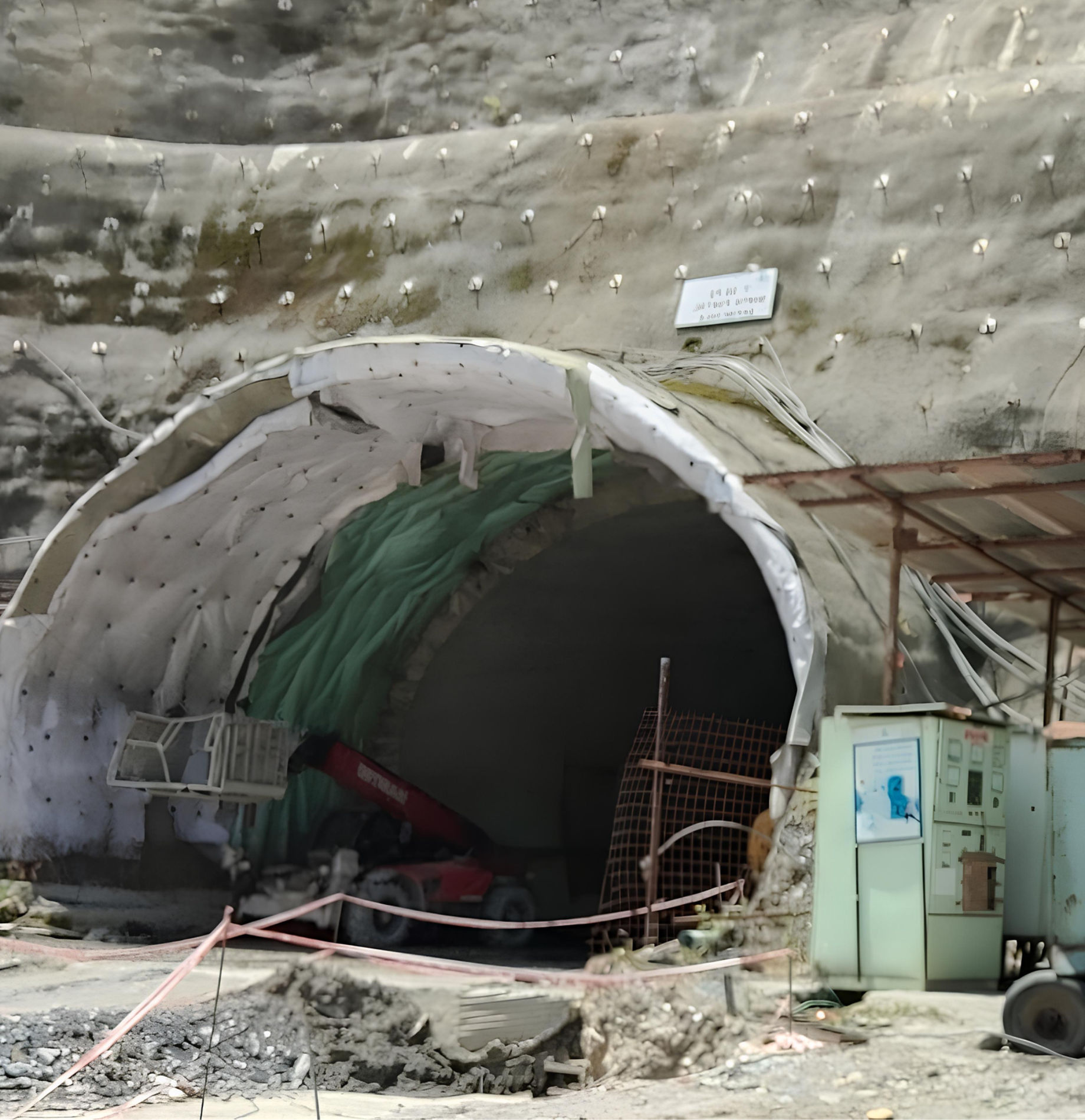

T-1 is the first tunnel in the 272 km USBRL corridor, passing through the Himalayan Main Boundary Thrust. At 3.3 km length with 750 m Dramix® 4D fiber lining, it sets the benchmark for durability and resilience in one of the most challenging geological zones of the entire project.

T-1 faced some of the most demanding conditions in USBRL, including passage through the Main Boundary Thrust with complex geology, rugged Himalayan terrain, and major water inflows. These factors made excavation and final lining stability critical, while logistics and remote access compounded the challenges.

T-1 adopted a robust cast-in-place lining design using Dramix® 4D 80/60 BG steel fibers to overcome severe ground and water challenges. The final lining, 0.60 m thick C30/37 concrete, included fibers at 45 kg/ m³ over 750 m of the 3.3 km tunnel. Dramix® 4D provided superior crack control, post-cracking ductility, and resilience against high groundwater pressures, reducing heavy rebar requirements and enabling safer, faster construction. This was one of the most geologically demanding tunnels of USBRL, and the fiber solution ensured long-term performance for a 100-year design life. Local manufacture of Dramix® in India ensured uninterrupted supply, crucial for progress in such difficult terrain.