Download

Please provide the following details :

This field is required

This field is required

Please enter valid email (e.g. johnsmith@domain.com)

Please provide the following details :

This field is required

This field is required

Please enter valid email (e.g. johnsmith@domain.com)

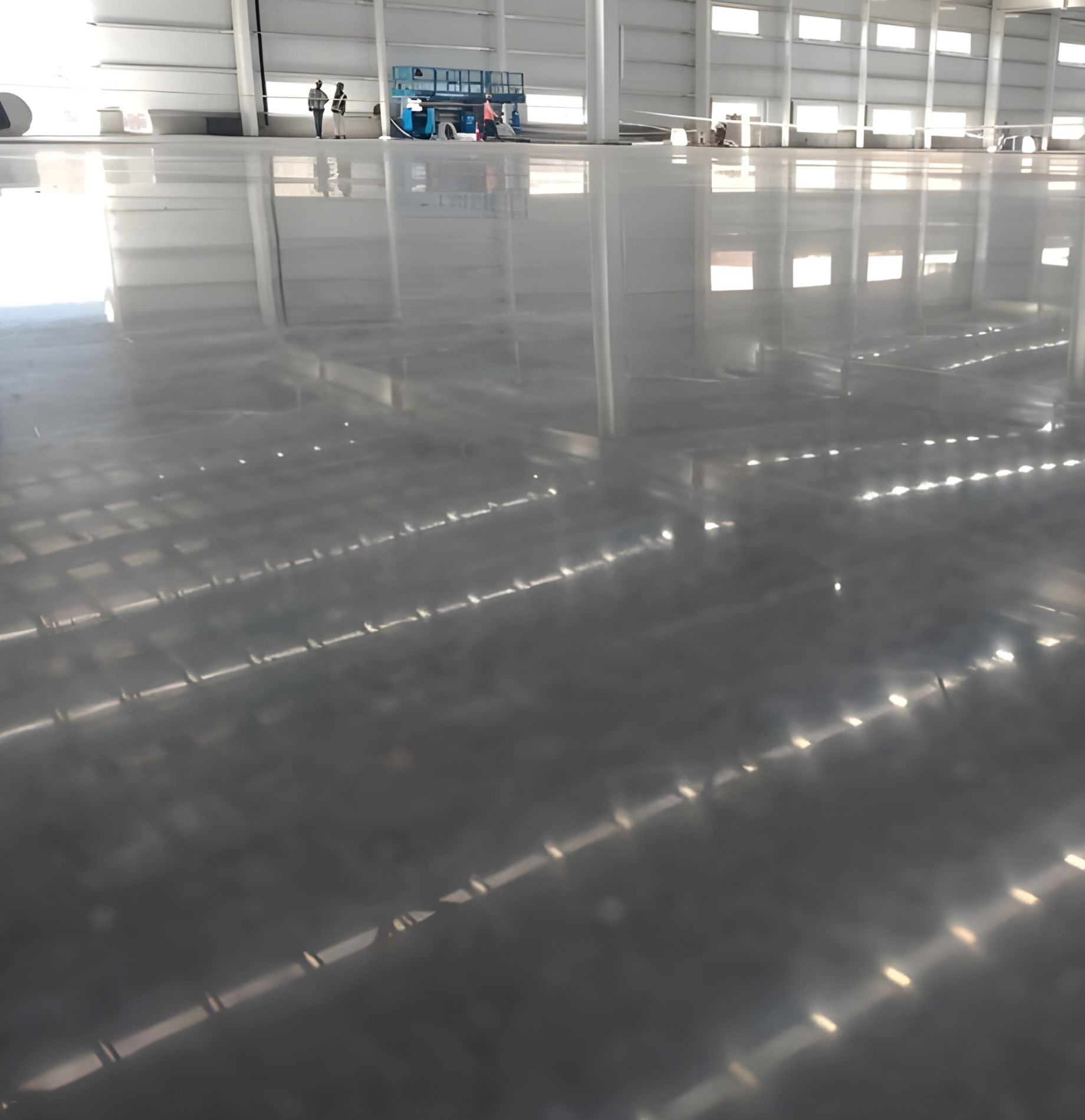

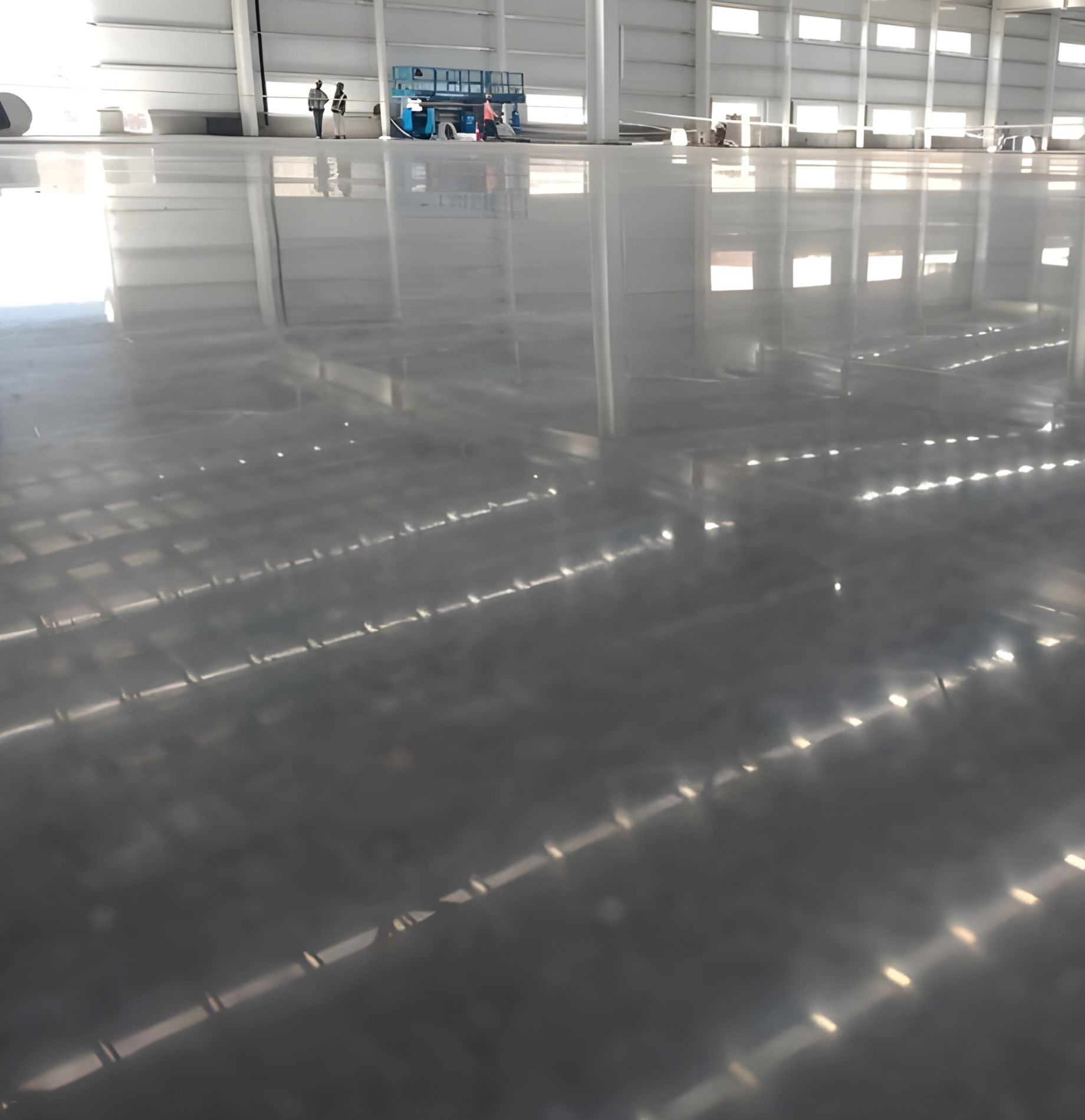

A long-standing client since 2014, the customer entrusted us to deliver customized flooring for their new facility with zones like engine, assembly, and paint shops. Each zone had unique design and load requirements, making it essential to balance durability, performance, and project timelines.

Each shop floor had distinct technical needs—high durability and jointless execution in the paint shop, and cost-effective solutions in the assembly area. The client also aimed to reduce rebar usage, meet tight construction schedules, and ensure on-site safety, all while aligning with sustainability and ESG objectives.

We implemented a zone-wise f looring strategy with Dramix® steel f ibres: jointless floors with 25m+ joint spacing in high-performance areas like the paint shop, and saw-cut floors with 4m grooves in standard zones. Eliminating rebar reduced labor, accelerated construction, and improved site safety. Fibres were mixed at the batching plant, simplifying logistics. Local manufacturing in India ensured faster lead times, improved material availability, and dependable project servicing. Backed by global expertise across diverse floor types and industries, the Dramix® solution delivered proven performance, durability, and long-term reliability— aligned with the client’s technical and sustainability goals.