Download

Please provide the following details :

This field is required

This field is required

Please enter valid email (e.g. johnsmith@domain.com)

Please provide the following details :

This field is required

This field is required

Please enter valid email (e.g. johnsmith@domain.com)

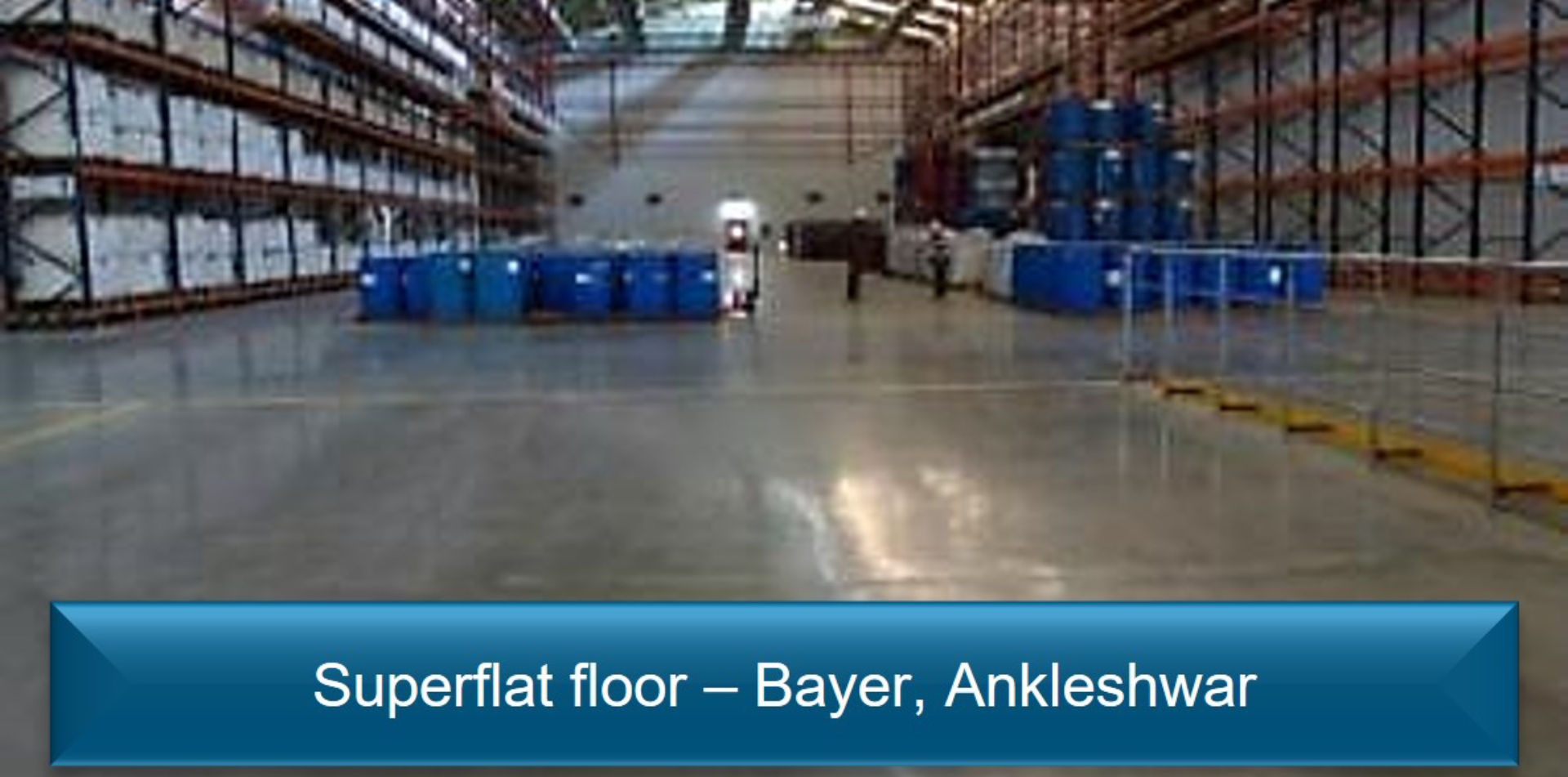

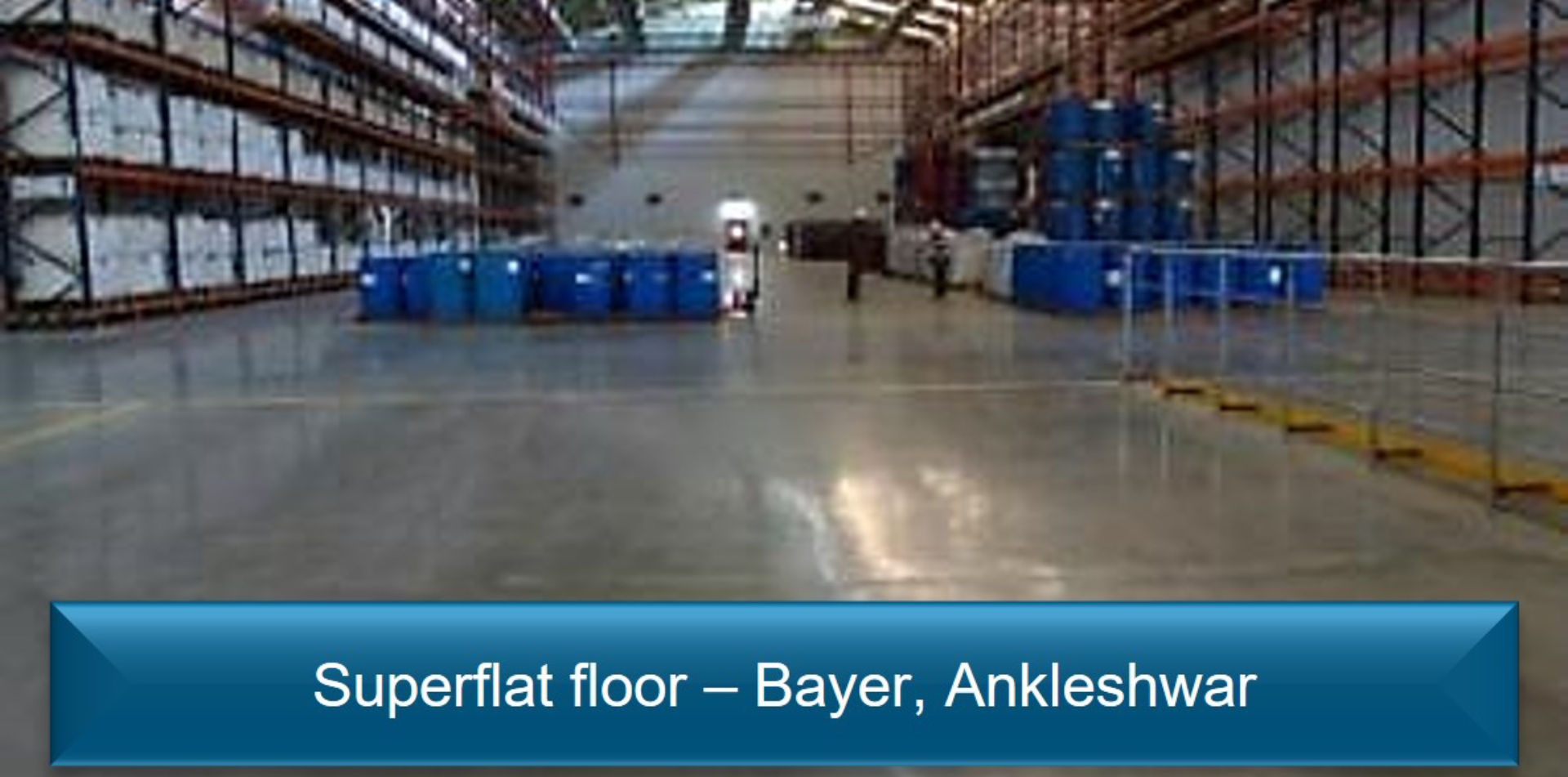

Bayer Cropscience Limited, a multinational agricultural company, set up a warehouse facility in Ankleshwar GIDC, Gujarat, India, covering an area of 20,000 sq. meters. Crete Colors India Pvt. Ltd, a Malaysian flooring contractor, was awarded the project. This project was significant as it was the first super flat floor in India, and the flooring contractor made their entry into India with this project after successfully completing a Bayer floor in China.

This project presented several challenges, as it was one of the first super flat floors executed in India in 2012. The importance of floor flatness and levelness of flooring was just beginning in India. The flooring contractor had to ensure that the project achieved the desired level of flatness, levelness and tolerances for continuous, 24/7 warehouse operations.

A saw-cut flooring solution using Dramix® 3D not only achieved the desired level of flatness, but it eliminated all conventional mesh, which saved a lot of construction time and costs. To achieve the desired level of flatness and levelness, we offered a saw-cut floor solution, eliminating the conventional mesh completely. We used Dramix® 3D 80/60 BG, a steel fiber reinforcement product with a dosage of 20 kgs per m³ and M 30 Concrete. As a result, the project was successful, and the flooring contractor made their mark in India with this project.

As a result, the floors of the Linder facility reinforced with Dramix® 3D are highly resistant to impact and abrasion. By eliminating rebar, accelerating the speed of construction, and using less concrete, project costs were reduced by around 30%. Moreover, by reducing the amount of concrete used, the project met Linder’s sustainability objectives with the project.

As a result, the floors of the Linder facility reinforced with Dramix® 3D are highly resistant to impact and abrasion. By eliminating rebar, accelerating the speed of construction, and using less concrete, project costs were reduced by around 30%. Moreover, by reducing the amount of concrete used, the project met Linder’s sustainability objectives with the project.